-

home dongguan Houjie Industrial Park

From Design to Manufacturing: The Perfume Packaging Process Explained

[ad_1]

The world of perfumery is a highly competitive and luxurious market, where even the smallest details can make a significant difference in product quality and customer satisfaction. One of the most critical factors in setting a perfume apart from the rest is its packaging. From design to manufacturing, the perfume packaging process requires great attention to detail and a deep understanding of the target audience, market trends, and brand identity.

Design Phase

The design phase is where the magic begins. Perfume manufacturers and designers work together to create a concept, considering factors such as the brand’s style and image, the target audience, and the type of fragrance. The design process involves several stages, from initial ideas to conceptualization, prototyping, and refinement.

A designer’s goal is to create a visually appealing, functional, and cohesive design that complements the fragrance and meets the brand’s expectations. This may involve researching market trends, analyzing competitor packaging, and gathering feedback from focus groups or customer surveys. The design phase is also where the bottle shape, size, color, and materials are selected, as well as the label, cap, and any additional packaging elements.

Prototype Development

Once the design is finalized, a prototype is created to test the overall look, feel, and functionality. This is an essential step, as it allows for the testing of materials, color accuracy, and potential production challenges. The prototype phase helps to identify potential issues and make necessary adjustments before moving forward with mass production.

During this stage, the design team will also work on creating a 3D model of the packaging, which can be used for further design refinement, and even to create a mockup of the product on the shelf.

Manufacturing Phase

With the design and prototype phase complete, the manufacturing phase begins. This is where the packaging is produced on a large scale, using machinery and equipment designed specifically for this purpose. During this stage, the final touches are added, such as labeling, packaging, and any additional processes required to meet quality standards.

Manufacturing is a complex process that requires precision, attention to detail, and strict quality control. The manufacturer must ensure that the produced packaging meets the agreed-upon specifications, and that all materials and components meet quality and safety standards.

Quality Control and Packaging

Before the final product is released, a thorough quality control check is performed to ensure that the packaging meets the required standards. This involves inspecting every aspect of the packaging, from the bottle shape to the label, cap and any additional elements. The goal is to ensure that the packaging is not only visually appealing but also functional, durable, and meets all necessary regulations.

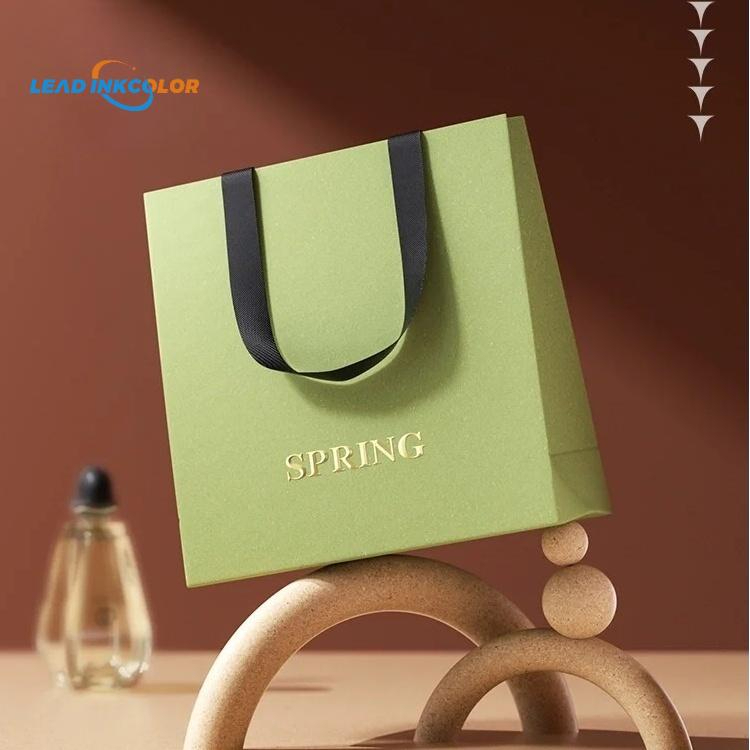

Once the packaging has passed the quality control checks, it is ready for final packaging, which may involve placing the product in a box, bag, or other container, as well as adding any additional marketing materials, such as brochures or instructional guides.

The perfume packaging process is a complex, multi-step process that requires great attention to detail, a deep understanding of the target audience, and a keen eye for design. By understanding each stage, from design to manufacturing, perfume manufacturers can create packaging that truly stands out in the market. In this article, we have explored the key stages involved in creating a perfume’s packaging, from initial design to final quality control check. By considering these stages, perfume manufacturers can ensure that their product is packaged in a way that will make it stand out on store shelves and in customers’ minds.

FAQs

Q: What is the most important factor in designing perfume packaging?

A: Understanding the target audience and their preferences is key to designing effective perfume packaging.

Q: Can I use any material for perfume packaging?

A: No, all materials used in perfume packaging must meet quality and safety standards to ensure they are safe for use and meet regulatory requirements.

Q: How long does the design phase typically last?

A: The length of the design phase can vary depending on the complexity of the design, the number of iterations, and the client’s feedback.

Q: What is the purpose of the prototype phase?

A: The prototype phase helps to identify potential issues and make necessary adjustments before moving forward with mass production.

[ad_2]