-

首页 东莞厚街工业园

The Impact of Automation on Perfume Packaging Manufacturing

[ad_1]

The Impact of Automation on Perfume Packaging Manufacturing

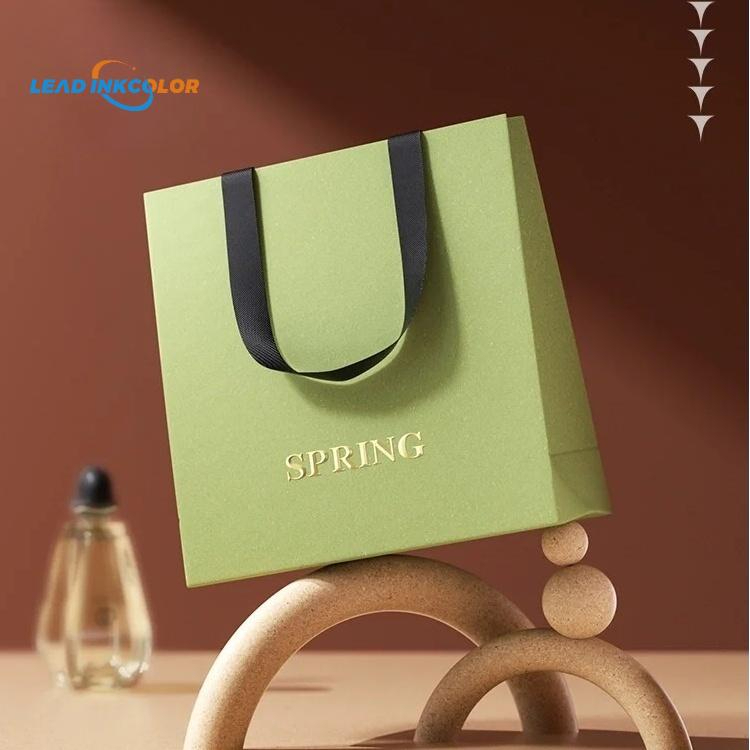

Perfume packaging is a highly competitive industry that relies heavily on the efficient production of high-quality packaging materials to meet the demands of the cosmetic and fragrance market. With the rise of automation, the perfume packaging manufacturing process is undergoing significant changes, affecting various aspects of the industry, including production speed, product quality, and costs. In this article, we will explore the impact of automation on perfume packaging manufacturing, its benefits and challenges, and the future prospects of the industry.

Introduction

Perfume packaging manufacturing involves the design, production, and finishing of various packaging materials, such as glass, plastic, and paperboards. The process involves a range of activities, including injection molding, printing, cutting, and assembly. Traditionally, perfume packaging manufacturing has been a labor-intensive process, relying heavily on manual labor and specialized equipment. However, with the advent of automation, the industry is witnessing significant changes, driven by advancements in technology and increasing demand for high-quality products.

Benefits of Automation in Perfume Packaging Manufacturing

The integration of automation in perfume packaging manufacturing brings numerous benefits to the industry, including:

- Increased Production Speed: Automation enables the faster production of packaging materials, reducing production time and increasing the overall throughput. This is particularly beneficial in meeting tight deadlines and fulfilling growing demand for perfumes.

- Improved Product Quality: Automated machines and systems ensure consistent quality and accuracy, reducing the risk of human error and defects. This leads to higher-quality packaging materials that meet or exceed industry standards.

- Reduced Labor Costs: Automation minimizes labor costs, as machines can work 24/7 with minimal supervision. This reduction in labor costs enables companies to allocate resources to other areas of business, such as product development and marketing.

- Enhanced Efficiency: Automated systems optimize the production process, streamlining workflows and reducing waste. This leads to increased efficiency and productivity, allowing companies to compete effectively in the market.

- Improved Safety: Automation eliminates the risk of accidents and injuries associated with manual labor, creating a safer working environment for employees.

Challenges of Automation in Perfume Packaging Manufacturing

While automation brings numerous benefits, it also presents several challenges, including:

- High Initial Investment: Implementing automated systems requires significant investment in new equipment and software, which can be a barrier for small and medium-sized businesses.

- Complexity: Automated systems can be complex to set up and maintain, requiring specialized expertise and training.

- Dependence on Technology: Automation relies on technology, which can be vulnerable to technical issues and downtime. This may impact production and affect the company’s reputation.

- Qualification and Training: Employees may require training to operate and maintain automated systems, which can be time-consuming and costly.

- Adaptability: Companies may face challenges in adapting to changing market demands and updated technologies.

Future Prospects of Perfume Packaging Manufacturing

The perfume packaging manufacturing industry is expected to continue evolving with advancements in technology. Some of the trends and developments that will shape the future of the industry include:

- Increased Focus on Sustainability: With growing consumer awareness of environmental issues, the industry will focus on more eco-friendly materials and packaging solutions.

- Customization: Automation will enable companies to create customized packaging materials in various shapes, sizes, and designs, catering to individual brand requirements and preferences.

- Further Integration of Internet of Things (IoT): The integration of IoT technology will enable companies to monitor production in real-time, optimize processes, and predict maintenance requirements.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML will be applied to improve production processes, optimize workflows, and predict consumer behavior and preferences.

Conclusion

The impact of automation on perfume packaging manufacturing is significant, transforming the industry in various ways. While it presents challenges such as high initial investment and dependence on technology, automation brings numerous benefits, including increased production speed, improved product quality, and reduced labor costs. As the industry continues to evolve, companies must remain adaptable, invest in employee training, and adopt sustainable practices.

[ad_2]